Lynden is known for providing innovative solutions to its customers. In a new twist on the term 'holding pen,' Lynden created a specially designed rack to hold surfboards for damage-free ocean transit. "There will always be a market for surfboards in Hawaii," explains Los Angeles Service Center Manager James Bisho, "so why not be the leader in providing cutting-edge transportation from the mainland to the islands?"

Lynden handles just about any type of freight imaginable from Los Angeles to Hawaii - from heavy machinery to perishable fruit to solar panels - via both air and ocean, full-container-load (FCL) and less-than-container-load (LCL). Coby Peterson of Marko Foam Products approached Lynden about shipping foam surfboard 'blanks' from LAX to Honolulu knowing they would be stowed in a container, but he didn't expect a special rack designed for just his freight. Lynden's Business Development Manager Maggie Parks couldn't wait to take Peterson's call. "I knew we could help him with this unique product," she says. "We thrive on and excel at requests like this. We are very good at creating solutions and showing nimbleness with how we can handle freight."

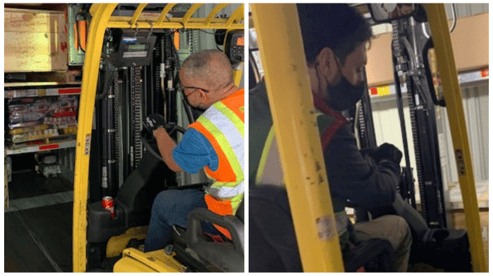

Lynden's 40-foot containers are equipped with Kinedyne Kaptive Beam® decking systems that can be adjusted at multiple levels to stack freight in a variety of configurations. The specialized containers are the only ones available in Hawaii and, with containers now in short supply, the 'sea cans' expand Lynden's shipping capacity at a critical time.

"With the Kaptive Beam® system, we can carry more cargo per container. Customers save time and money and realize increased value with every load," Parks explains. "I am receiving positive feedback from our surfboard customers on this new option for surfboards and blanks. We have taken a collaborative approach, finding better ways of packing and moving the boards."

"Lynden has greatly increased our business on the Hawaiian Islands by providing a reliable and cost-effective shipping method to better serve our customers," says Peterson, Marko's Manager of Business Development and Marketing.

Besides Marko Foam Products, based in Huntington Beach, CA, Lynden is now handling shipping for other California companies including Catch Surf and Pyzel Surfboards. Pyzel, a leading global surfboard manufacturer, is moving full containers of boards and blanks to Honolulu inside Lynden's Kaptive Beam®-configured containers.

Lynden is well-known as one of the largest providers of air freight forwarding between the mainland and Hawaii, but it's now gaining recognition for ocean service with a variety of LCL options. The multi-mode capabilities of choosing barge, steamship or air and mixing the modes to speed up or slow down delivery for changing timelines and budgets is a selling point.

"Our service levels give us multiple layers of experience and options to offer customers," explains Stuart Nakayama, Lynden Vice President of Trade Lane Development. "Ocean LCL has always been a part of our service, but things really took off last year when we added our containers equipped with the Kaptive Beam® system, which allows us to manage our loads more effectively and price competitively. We can mix and match heavy, odd-sized loads, double-stack and handle just about anything - from tall pallets of odd-sized freight like surfboard blanks, to smaller pieces."

With backed up ports, slowed supply chains, and a shortage of containers, ocean shipping has been anything but smooth sailing this year. "The ocean shipping industry is still feeling the effects of the pandemic. It's like a snake trying to eat a rabbit," Nakayama says. "Log jams at port of entry are still occurring and impacting the Southern California market. It used to take four days to get large vessels unloaded, reloaded and leaving the port. Now it takes weeks. In my 33 years in the industry, this is unprecedented. As the experts, we are here to help our customers navigate these sometimes choppy waters and make sure we take care of their logistics needs."

Despite the current challenges, Lynden employees still manage to pull off wins for customers on a routine basis. Recently Lynden's Los Angeles team worked through a weekend after an urgent shipment arrived after deadline on a Friday night. They knew their customers at a well-known grocer had a division vice president arriving on Monday to inspect the store. The bagged salads had to be on the refrigerated shelf when he arrived. So they flagged the perishable freight, quickly split the cargo, prepared the documents and booked space on the first available flights. The store passed the inspection.

"Whether it's working overtime, creating new ways to protect freight, or offering the latest and best equipment to ship that freight across the Pacific, we are always thinking of our customers," Nakayama says, "even if it means building holding pens for surfboards!"

Topics from this blog: Hawaii Retail Multi-Modal Ocean