Topics from this blog: Lynden Safety United States Construction AML Featured Northland

We are looking for motivated, talented, and career-oriented individuals in a variety of positions.

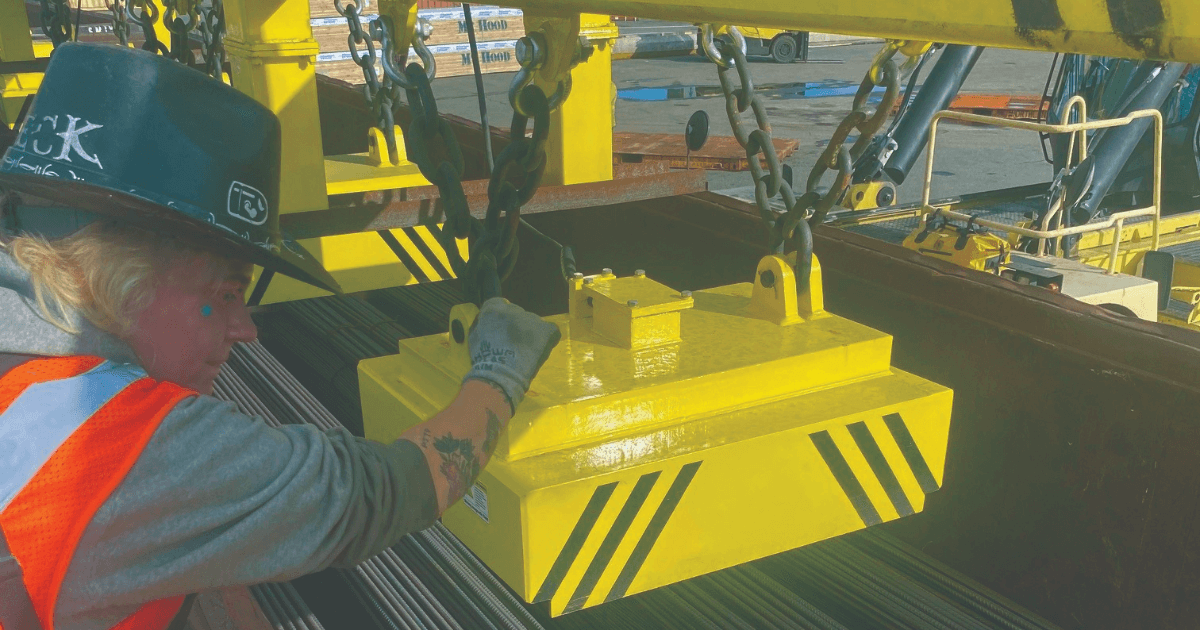

Northland Services Equipment Operator Jordan Dickson guides the magnet into the rail car.

Northland Services Equipment Operator Jordan Dickson guides the magnet into the rail car.

Alaska Marine Lines recently expanded its equipment options with a new magnetic picker, improving safety and efficiency in handling rebar shipments in Seattle. According to Continuous Improvement Manager Jay Marchand, the previous method of moving bundles of rebar required two people inside an open rail car to attach slings around the bundles.

The self-powered magnetic picker keeps employees safely outside the rail car with one operating the machine and the other guiding the magnet to the rebar bundles. According to Oliver Zidek, Northland Services General Manager, a gain in operational efficiencies is a benefit, but that is secondary to the increase in safety. "We are excited to have this tool reduce risk from this type of transfer operation," he says.

According to Jay, the magnetic picker general concept was out in the market, but AML's layout and use was specific. The AML team toured the local rebar handling yard at Nucor Steel to see how magnetic cranes worked. Previous experience with similar powered equipment and history of handling 60-foot rebar was helpful when evaluating different manufacturers. Ultimately a vendor from Colorado was chosen to build the machine due to its technical expertise and ability to build to specific requirements. "Between production delays, technical hurdles, tariff instability, and fluctuating shipping costs, delivery of this machine has been a year in the making," Jay says. "We're glad it's here, and we look forward to many years of safe use."

Topics from this blog: Lynden Safety United States Construction AML Featured Northland

We are looking for motivated, talented, and career-oriented individuals in a variety of positions.